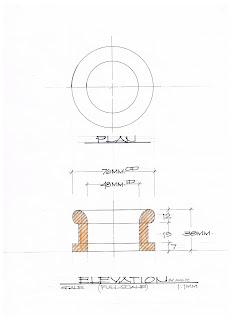

The engine the SK carbs will be used on is my 1600cc Mitsubishi 4G3x with a works Rally cam shaft #4, some mild head works and high compression pistons. Caluclations we made, so that this engine makes good torque and peak power at around 6000 RPM, dictated that we needed 30mm primary venturis, which should ideally be used in twin 40mm carbs. The SK's are 45mm and came with 36mm venturis. The carb body might be a bit too big, meaning we're giving up a bit of low end torque and tractability for street use, but it should be ok for top end power. It's a little bit of compromise to be able to run such a unique set of carbs. While the SK may use Weber jets, the primary venturies are unique to the SK. This made is necessary for us to fabricate our own using a process similar to how we made the velocity stacks.

The next thing that needed to be made was a throttle linkage. The SK's came with a synchonizer to mate the two carbs together, but no form of linkage at all, so we started by gutting part of linkage of a dead set of Keihin CVK carbs that I had laying around in the shop. This was ground down and modified to fit in between the synchonizer to give the cable somewhere to hold on to.

A Honda City throttle cable was next, chosen because it was just about the right length and most importantly it's business end matched to Keihin cable loop, and with a little bit of modification to shorted the protuding edges it was perfect.

A cable stopper bracket was fabricated to hold it all in place.

The decision to use the Keihin loop, which was small, and the fact that the Lancer originally used a mechanical linkage, not a throttle cable to actuate the carb meant the next thing we had to sort out was how to connect the cable to the accelerator pedal. Due to the small diameter of the Keihin loop, I wanted something that would open the carb progressively and after studying how we could possibly modify the original throttle pedal, we decided it would be better to just build one from scratch.

A big loop for the other end of the cable to compensate for the smallness of the carb end in order for the carbs to open more progressively. This one was fabricated from scratch.

The rest of the pedal was based on the original one, using a small mechanical linkage to move the throttle cable.

All the parts were powdercoated before being installed in the car.

A throttle return spring bracket was also fabricated. Adjustable mounting options let us alter the spring tension to change the feel of the carbs.

Here's me reinstalling the carbs back into the car.

Have not been able to start the car yet to test the carbs after cleaning since we are waiting for a new Oil Cooler to install on the car. I will post an update later once we get everything running.

One last thing, not exactly part of the carbs, But just as necessary. Because of the the tight space in the car's engine bay in order for the synchronizer tool (aka Air flow meter) to fit into the barrel of the No.4 carb be had to offset our master cylinder for the AP Lockheed brake system, in order to give clearance. This was done using a custom made bell crank system. Otherwise the pot of the master cylunder would have been right in front of the velocity stack of No. 4 with only a few mm clearance in between.

.