A quick background. A velocity stack is that trumpet or bell mouth shaped fixture that smooths incoming air into an intake tract. This works by eliminating 'pinch zones' that would occur if the air were to enter a straight pipe. Quite popular and definitely a cool thing to have on a set of side draft carbs or throttle bodies. They enhance the induction noise the carbs make.

There are a number of shops here in the Philippines that can make a set, and most are actually quite affordable. The best deal I found was from this guy called Mang Orly, with a set of (what looks to me like) spun aluminum velocity stacks costing around 2500 Pesos. They looked pretty good too and have an option to even be anodized. I was pretty much ready to put in an order for a custom set for the SK's. But, because we can... We just had to go make our own.

Aluminum spinning is by far the most common and efficient way to make velocity stacks. This is how original Weber stacks are made. This however requires special equipment and of course the skill to spin aluminum. Look up videos of it on YouTube, it's an art form all on it's own. We however had neither the equipment or the skills. So we had to go with the relatively more inefficient (read as expensive) method of machining our stacks out of solid billet aluminum. Machining though does produce a nicer looking product (in my opinion).

So here's how we made it.

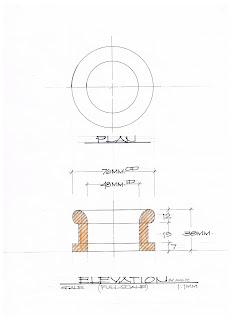

It all starts with a plan. Internal diameter of 48mm to match the throat opening of the 45mm SK carbs. 76mm outside diameter to give enough wall thickness after machining to make sure they are sturdy and would have a fairly large bell mouth opening. The bigger the bell mouth the more effective it is. 38mm height due to space constraints, would have wanted at least 50mm tall, but no way that was going to fit the Lancer.

All the machine work would be done at our factory by our very talented mechanic using a 70's vintage Harrison lathe machine.

The first order of business was to get the material. I ordered 3 inch thick solid T6 Aluminum billet from our supplier and we made a few custom blades to shape the block of metal into our sexy stacks. This is the block of aluminium billet we started with, to it's right a custom made profiling blade for shaping the bell mouth of the stack. 1 blade for each shape and one special blade to bore out the internal diameter. I won't go into detail for the special tools made... Let's call them a trade secret, but the one picture below should give an idea of sorts..

A pilot hole is first drilled down the center of the billet in order to start machining the internal diameter. We used the biggest drill bit we had which I think was around 25mm.

The using the first of our special blades machined this from the inside out to 48mm.

This was then cut down to size for our 38mm height.

Using the second special blade, the bell mouth was machined. While doing the actual item, I decided not to follow the plan we had drawn up because it would look nicer if the bell mouth extended all the way to the outside edge instead of rounding it out.

Next was to shape the outside of the stack. This used a not so special blade to remove some material from the outside, and another special blade to shape the outside lip profile of the stack. It was also sanded and polished while spinning on the lathe.

Once formed holes were drilled to match the studs on the carb. Also had to file the sides down a bit to give space for the retaining bolts to be turned down as I discovered while test fitting.

In the end, I'm quite happy with how the finished product turned out. They look the business and are quite impressive. The cost of the billet aluminum alone was about as much as I would have paid to have Mang Orly make a set of stacks, and if the around 8 whole days of work it took to make these stacks were factored in as cost with equivalent overhead for running the machines, it pushes the cost of making these stacks to a price range that some people will think is crazy. Although, of course solid billet stacks really do cost much more than spun ones as I've seen tuners in other countries make them. Locally I don't know of any other tuning shop that makes solid billet velocity stacks.

No comments:

Post a Comment